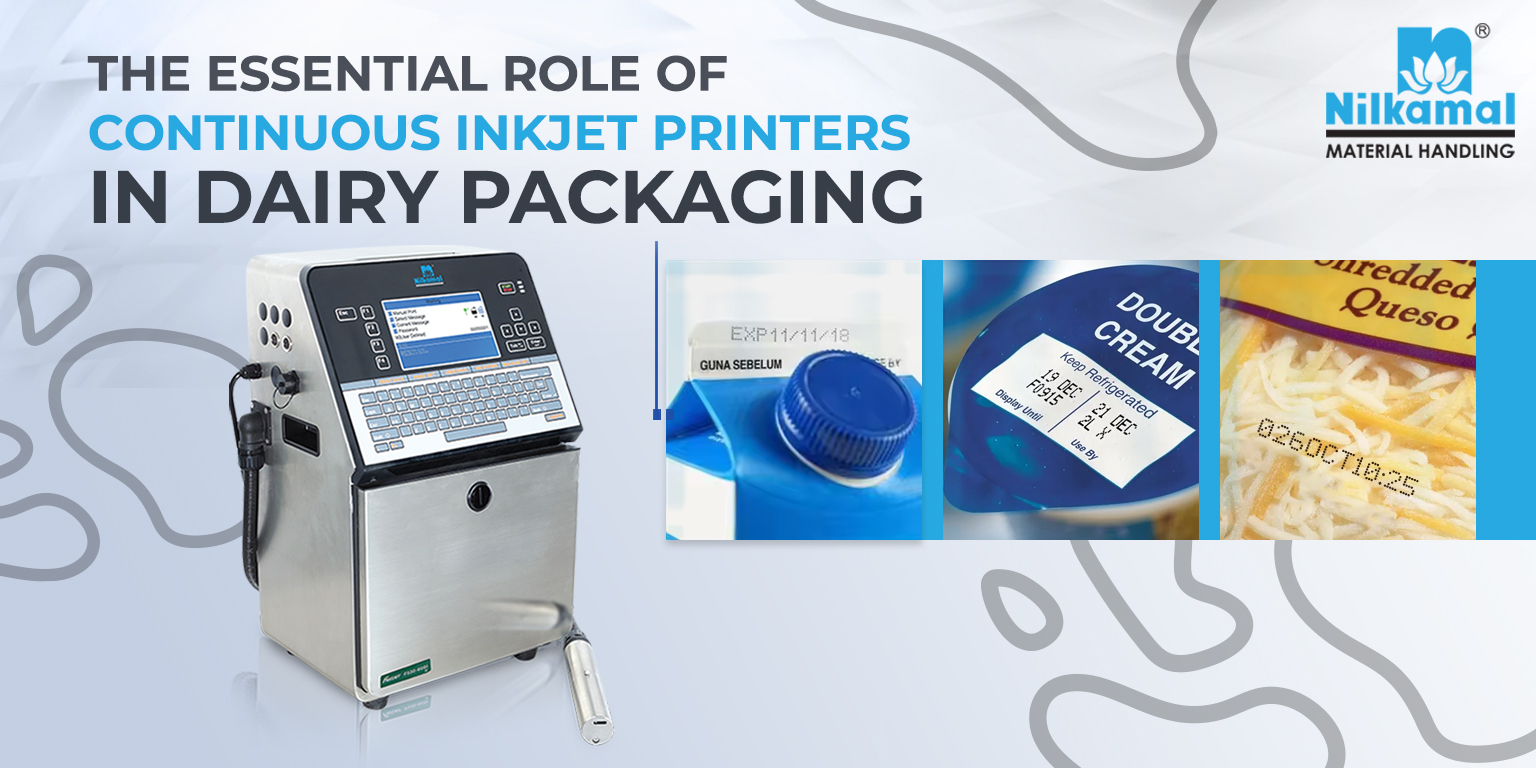

It is impossible to imagine a household, restaurant, or hotel without milk and dairy products. From milk, butter, and ghee to cottage cheese, curd, and buttermilk, different milk products are used for various purposes in the kitchen. But since dairy is highly perishable, consumers look for essential product details on the packaging before buying them. And when these details are printed using a continuous inkjet printer, they are legible and durable. Here are some essential details the dairy industry should print using continuous inkjet printers:

Packaging and Expiry Dates

All milk cartons, packets, bottles, etc., as well as the packaging of other milk products, should contain packaging and expiry dates in clear, legible print. This helps consumers be assured that the product is not being used after its shelf life has passed.

Lot or Batch Numbers

Stating the batch number of a dairy product makes it easily traceable in case there is any defect in the entire batch of products. So, it’s mandatory for the dairy industry to clearly state lot or batch numbers on the product packaging.

Net volume

The total volume or quantity of product contained in the package should be accurately specified in the packaging.

QR code

QR codes are important in packaging, because they enable brands to interact with customers and improve customer experience. They also help businesses track their products effectively. With continuous inkjet printers, dairy companies can easily print these codes clearly on their products.

Maximum retail price

Printing the MRP on packaging is a must for all products being sold in the market. CIJ printers are widely used to print this information on dairy packaging.

Continuous inkjet printers are the best choices to print such product details on dairy packaging, because the ink is resilient to moisture and weather conditions. Nilkamal’s F500 Series continuous inkjet printers entail an unconventionally simple, unipart design, making it extremely easy to use. They also ensure zero lockout hours, saving printing hours and increasing productivity considerably.

Our printers come with easily replaceable external filters, so those handling the printers can refill ink independently. Also, made of IP55 stainless steel, these printers are sturdy and durable. If you would like to start printing product information on your dairy products, we’d be glad to help you buy and install a continuous inkjet printer for your facility.